9500 EVOLUTION

9500 EVOLUTION

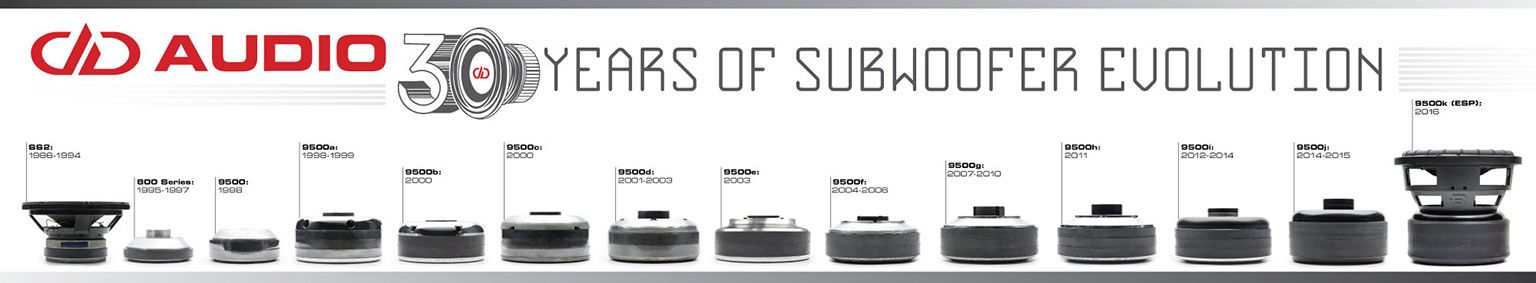

DD Audio is celebrating 30 years of bass domination by taking you on a journey through the world renowned 9500 Series evolution.

From the beginning, DD has continually worked to improve our designs to keep up with the newest technology and the ever changing styles of music flowing through our veins. This comprehensive list documents each model’s highlights, changes, and improvements. With each new model we were able to push new limits, and thus, continually increase the performance and durability of the product. We’ve learned a lot over the years, and each lesson has helped pave the way to our newly released 9500 ESP subwoofers.

At the end of the day, we feel the customers are the true judges of our products, and if the 9500’s legacy has anything to say, it’s that we’re doing something right.

DD Audio is celebrating 30 years of bass domination by taking you on a journey through the world renowned 9500 Series evolution.

From the beginning, DD has continually worked to improve our designs to keep up with the newest technology and the ever changing styles of music flowing through our veins. This comprehensive list documents each model’s highlights, changes, and improvements. With each new model we were able to push new limits, and thus, continually increase the performance and durability of the product. We’ve learned a lot over the years, and each lesson has helped pave the way to our newly released 9500 ESP subwoofers.

At the end of the day, we feel the customers are the true judges of our products, and if the 9500’s legacy has anything to say, it’s that we’re doing something right.

SS2: 1986-1994

The sub that started it all was built in the late 1980s and early 90s under the Resonance brand, and designed for use in bandpass and active studio subwoofers set-ups. The aptly named SS (Studio Subwoofer) utilized underhung voice coil topology coupled to a low moving mass design.

800: 1995-1997

For the 800’s we increased the top plate from 20mm thick, to 30mm thick. These were made in underhung designs, using edgewound ribbon wire coils (single magnet), and overhung designs using round copper wire (double stack magnet).

The 800 motor design was very strong compared to most other designs available in the market, especially in the overhung coil design. Our testing showed when coupled with high power amplifiers, it could easily overdrive the capability of the cones, spiders and voice coils.

For the next couple of years we continued using the 800 Series motors while we worked relentlessly with our trusted suppliers to develop stronger parts and refine the design further for the growing number of high power applications.

9500: 1998

Towards the end of the 800 Series the double stack motors customized for use in car audio applications started gaining in popularity, so much that we designated it as it’s own series. This is where the car audio legend known as the 9500 Series really begins.

9500A: 1998-1999

By the late 90’s we had virtually redesigned the car audio subwoofer as the world had known it. We developed coils, spiders, tinsel leads, cones, and motors specifically for high power car audio applications. These improved parts and manufacturing techniques are the cornerstone of the DD Audio subwoofer line you see today.

Improved Coil Design: Higher temperature round copper wire coils using aluminum formers and multiple layers of nomex wrapping to protect the glue joints from heat and strengthen the former. Laminated Fabric Spiders: Offered a higher level of control and more linear movement during peak excursion vs. traditional single cloth spiders. Multi-Strand Tinsel Leads: Burnt tinsel leads were a common problem with single strand tinsel designs. With our multi-strand technique the leads were able to carry high current loads without burning. Plus our new design was heat formable, allowing us to shape the leads in optimal pattern to stay clear of the cone and spider during peak excursion. Free Flow Cooling Motor: Helped to deal with the ever increasing thermal load from high power amplifiers. This system turned the speaker into a giant air pump; circulating cooling air through the motor and the voice coil.

9500B: 2000

The current method for cross drilling the top plates was hindering our ability to keep up with increased production demands. For the sake of production efficiency, we amended the original top plate venting method.

EROM Surrounds (Extended Range of Motion): Allowed for more control at high excursion while keeping the cone area as large as possible. SFB Cones (Synthetic Fiber Blend): Impregnated with Kevlar, this proprietary pulp mixture allowed us to increase the cone’s cross section, which added a significant amount of strength, without adding any mass.

Laminated Lead Wires: Eliminated lead wire slap at high excursion. Secondly, traditional hanging lead wires placed weight and tension on the cone, causing harmonic distortion. Our laminating technique put the lead to coil connection below the cone thereby restoring balance.

9500C: 2000

For the c revision we moved the cross venting to machined paths in the bottom of the top plate. The c revision also introduced a frame spacer to accommodate the need for increased coil length and suspension travel.

9500D: 2001-2002

To aid in production methods, the cross venting moved to the top of the top plate. Further advances were made in the development of the laminated leadwire system, and we changed the profile of our spiders. The new proprietary spider design incorporated higher rolls, which allowed for more excursion without increasing the spider diameter.

Direct Connect Speaker Leads: The d revision also introduced Direct Connect Speaker Leads. Direct Connect Leads are the most electrically efficient connections out there. This twisted and soldered connection reduces any signal lose to an absolute minimum.

9500E: 2003

When most companies were trying to dominate the world by building cheap subs, DD continued the refinement of our softs parts enabling our subs to further distance themselves from competitive brands.

It was during this time period that we also released a limited run of sound quality focused subs designed with underhung coils. We called these the 9100 series. They used a 9500 motor coupled with a custom machined top plate extension allowing for this subs unique underhung design.

9500F: 2004-2006

We increased the magnet diameter to 230mm, up from 220mm. This motor used 2 magnets of 25mm thickness.

We also continued to make improvements to Free Flow Cooling System design.

9500G: 2007-2010

We increased the magnet diameter to 230mm, up from 220mm. This motor used 2 magnets of 25mm thickness.

We also continued to make improvements to Free Flow Cooling System design.

9500H: 2011

This was an in-between motor. It possessed features of it’s predecessor, and what was to come. The top plate design from the g revision remained, but the pole piece was tooled for shorting ring mounting, and we added vents in the bottom plate for increased heat dissipation.

9500I: 2012-2014

The i revision saw an improved top plate design plus several other performance enhancements. We introduced our larger diameter composite spiders, and the 8 spoke frames with a larger spider landing to accommodate the new spiders.

We also started using black hard parts due to environmental concerns linked to chrome plating.

This revision added the ability to SuperCharge, and the pole piece was undercut below the top plate allowing for a more focused magnetic gap.

9500J: 2014-2015

In response to the shift in our customers listening styles we increased the magnet structure to a 75mm height allowing the j revision to accommodate our Z3 coils. This gave the 9500’s more usable travel which is needed in higher excursion applications, along with greater heat dissipation ability.

9500K (ESP): 2016

The ESP subs are products of over 30 years of subwoofer innovation. Everything we’ve learned along our journey has directed the evolution of our subwoofers; hence why we call it the Evolution Subwoofer Package. ESP allows us to address several performance issues plaguing standard subwoofer designs.

True Size Carbon Fiber Blend Cone (CFB): Allows for more cone area and bass output from a given box size while staying in designated size classes. The CFB composition employs a potent carbon fiber based cocktail to give you the highest strength to weight ratio of any pulp cone in the industry.

Vario-density Extended Range Of Motion Surround (V-ROM): Provides the ultimate in linear control at high excursion while still allowing for dynamic sounding bass reproduction. The control ribs allow for a continuously variable control system through expansion and contraction.

Super Frame (SFrame): Maximizes spider diameter, cone diameter, suspension travel, works as a secondary shorting ring and provides additional heat sinking for directing heat away from the coil.