9500

9500

RELENTLESS SCRUTINY

To take the 9500 Series to a higher state, refinements could no longer be mere upgrades, but a completed statement on quality and what is possible when you give everything and compromise nothing in the pursuit of unparalleled excellence.

RELENTLESS SCRUTINY

To take the 9500 Series to a higher state, refinements could no longer be mere upgrades, but a completed statement on quality and what is possible when you give everything and compromise nothing in the pursuit of unparalleled excellence.

Some of these technologies can be found in the Z Series, some in the 2508g,

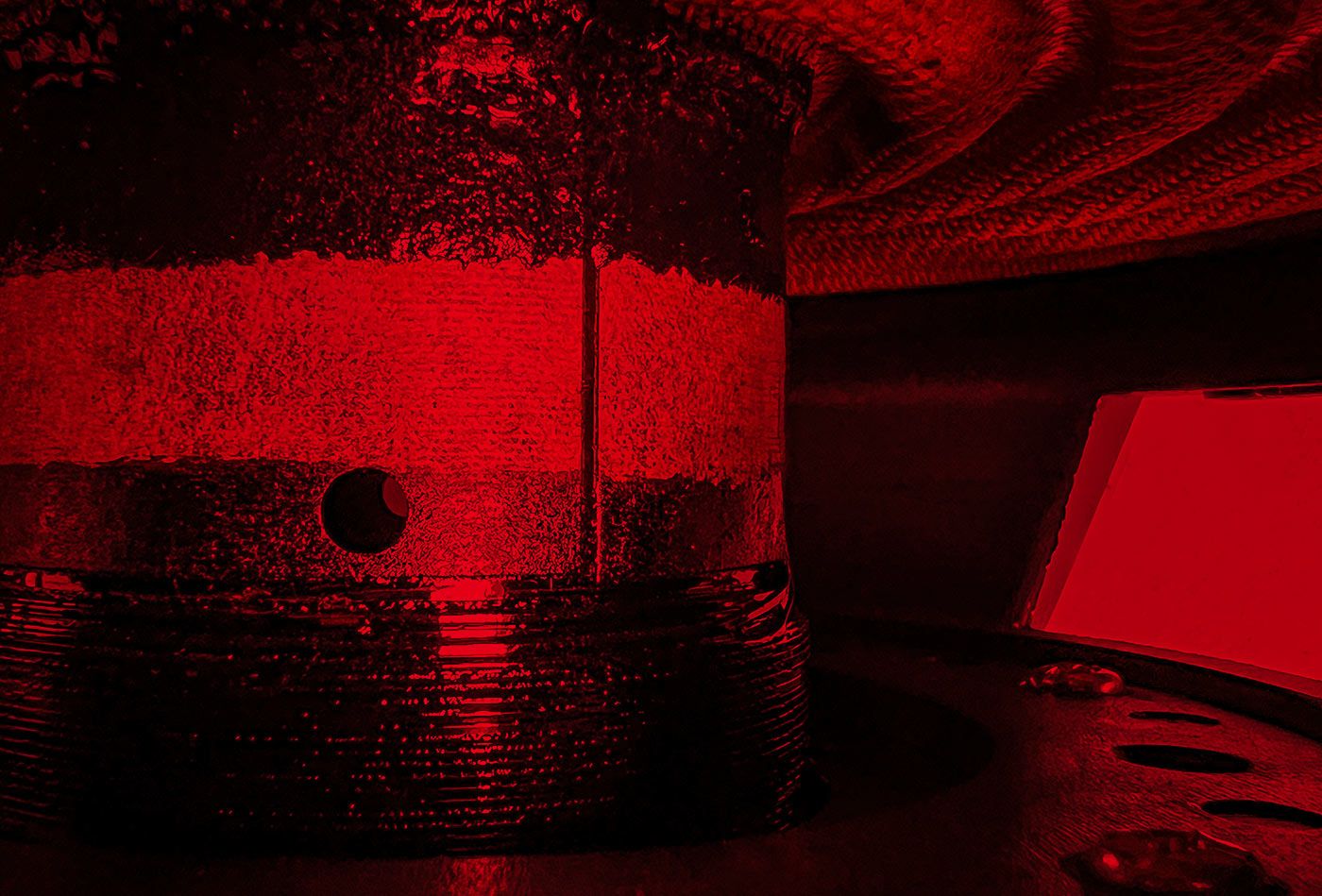

THE HEATSINK

The Dual Stage Heat Sink uses an internal aluminum tube insert to transfer heat away from the pole piece and voice coil and into the finned aluminum, backplate mounted, heat sink. This process of conduction and convection lowers the working temperature to safer levels,

The Dual Stage Heat Sink uses an internal aluminum tube insert to transfer heat away from the pole piece and voice coil and into the finned aluminum, backplate mounted, heat sink. This process of conduction and convection lowers the working temperature to safer levels,

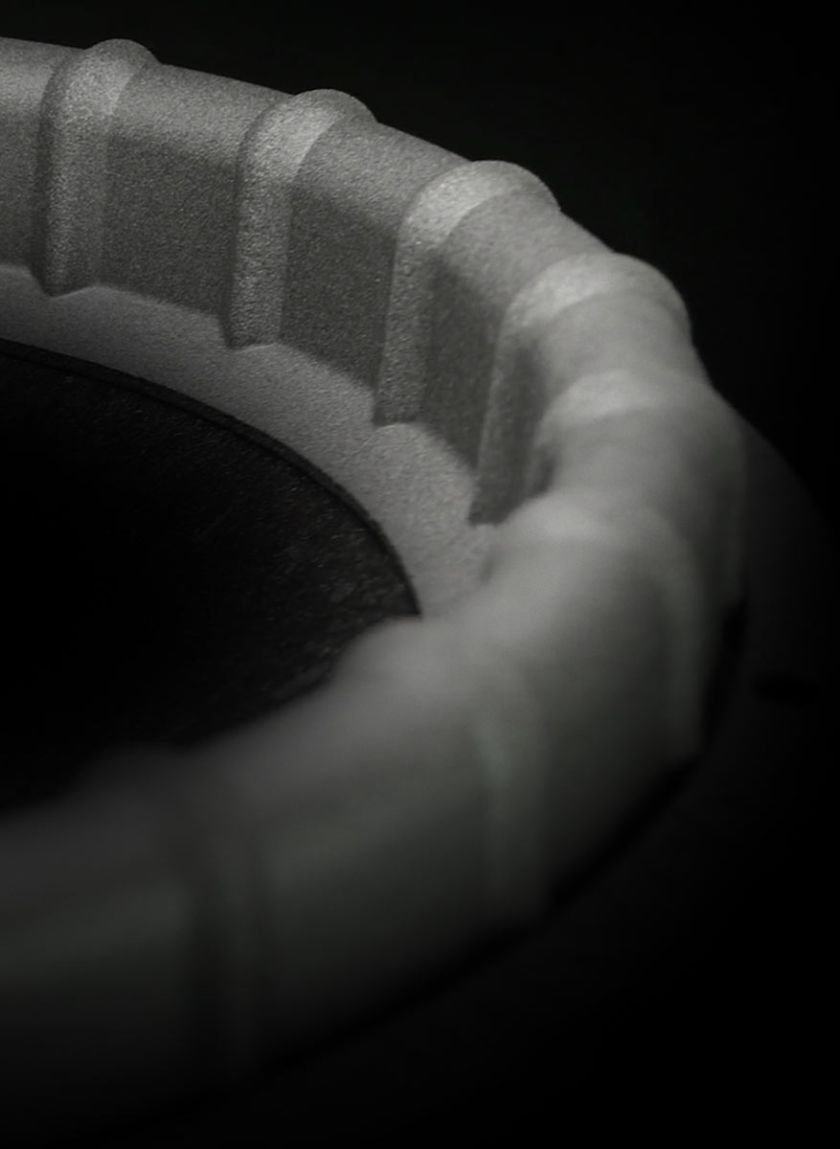

THE SURROUND

The 2nd generation V-ROM surround is debuting on the 15” L revision.

The 2nd generation V-ROM surround is debuting on the 15” L revision.

The new design offers added height for DD’s proven EROM surrounds, and with it, higher levels of excursion over maximum cone area. DD engineered variable density ribs to expand and contract as the surround is forced in and out of sine waves, essentially eliminating hysteresis and its negative effect on linearity, ensuring the highest possible stability.

The new design offers added height for DD’s proven EROM surrounds, and with it, higher levels of excursion over maximum cone area. DD engineered variable density ribs to expand and contract as the surround is forced in and out of sine waves, essentially eliminating hysteresis and its negative effect on linearity, ensuring the highest possible stability.

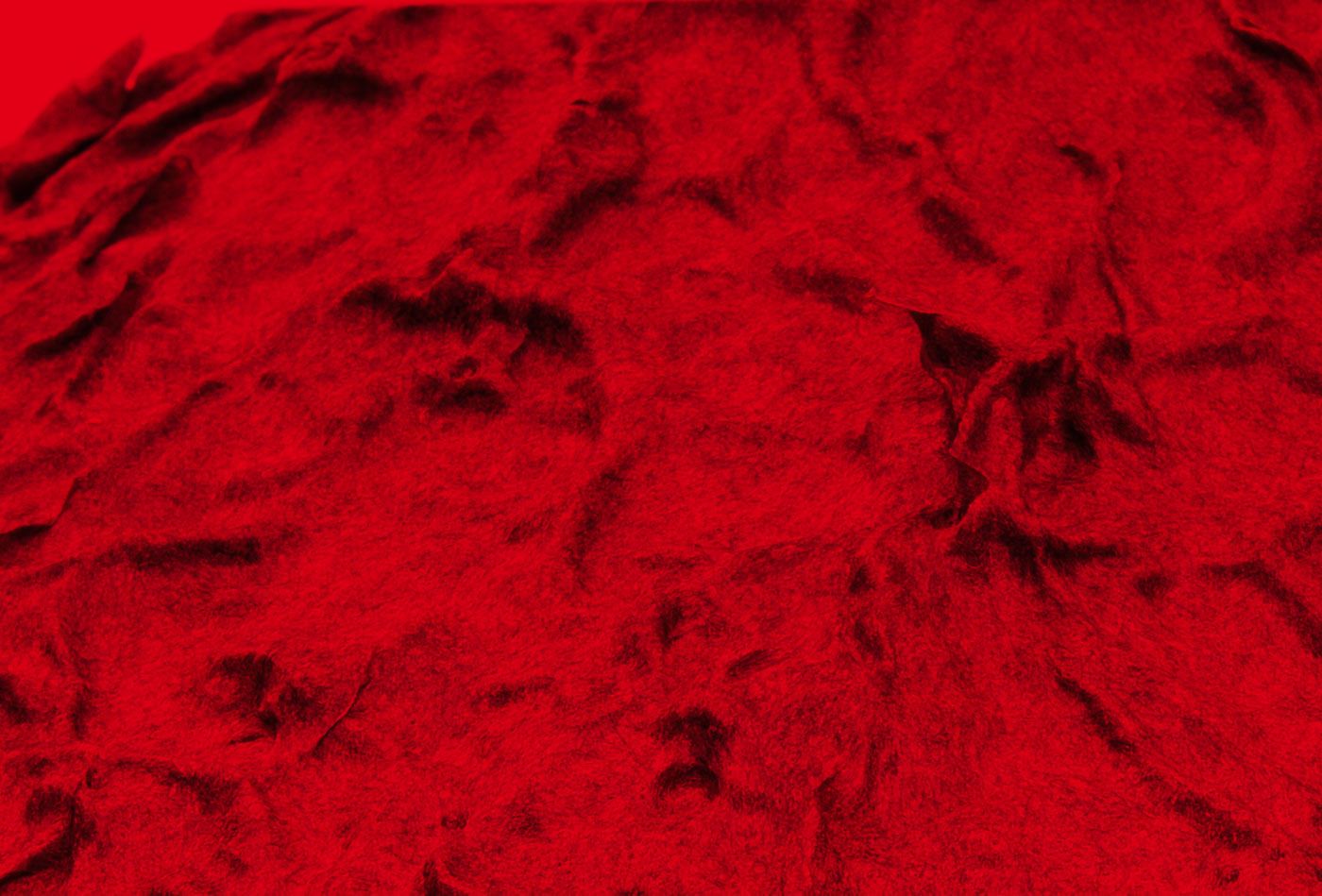

THE SPIDER

Complementing the improved surround is DD’s new, USA Made Iron Cloth Spider System.

Complementing the improved surround is DD’s new, USA Made Iron Cloth Spider System.

The new Iron Cloth Spider System continues the tradition of multilayer pressing to meet the Power Tuned stiffness targets, but with the added benefits of higher strength threads weaving through the double or triple layer configurations. The result is substantially elevated performance and long term durability.

*spider color may vary depending on production run – design, material and build quality remain the same

The new Iron Cloth Spider System continues the tradition of multilayer pressing to meet the Power Tuned stiffness targets, but with the added benefits of higher strength threads weaving through the double or triple layer configurations. The result is substantially elevated performance and long term durability.

*spider color may vary depending on production run – design, material and build quality remain the same

The 9500 Series voice coil is Made in the USA, and has evolved over generations to be the envy of DD’s competitors. Among the 5 layers in these complex formers are Nomex and Polyamide which insulate the coil, protecting the glue joints between the spider and coil former. These synthetic layers are sandwiched by dual aluminum layers, which transfer heat away from the voice coil windings (again, acting as a heat sink). The wire and adhesives are manufactured to endure the most extreme high temperatures and the coil thermosetting occurs over 2 baking and resin coating cycles. The double slit design helps to reduce distortion and inductance. In short, this voice coil has matured to include the best known materials and techniques available to deliver matchless performance.

The 9500 motor is a work of pure magnetic magic. DD AUDIO uses their own proprietary magnet tooling to maximize the surface area transfer from the low carbon back and top plates. The motor on the 9500 perfectly protects DD AUDIO’s reputation for having the tightest gaps in the industry, with minimal tolerances around the coil windings for increased gap flux. On custom orders, DD offers the option of SuperCharging the gap with neo to further increase flux by 30% or more. The motor also features DD AUDIO’s Free Flow Cooling System, which they engineered over 20 years ago. This system employs vents and cross vents running through the magnet gap, pole piece, top plates and back plates. The more excursion the speaker sees, the higher the airflow through the motor and around the coil. All motors use Faraday shorting rings to reduce distortion and inductance.

The 9500 Series is Made in the USA with as many Made in the USA components as DD AUDIO can reasonably acquire. Among those components is the USA made cone, engineered to be the lightest and stiffest pulp cone in existence. The key ingredient to its incredible strength to weight ratio is Carbon Fiber. Augmented by Kevlar and a myriad of synthetic and natural fibers, the cone is low density formed on non-press molds to increase the total cross section area, promoting a web of strengthening ribs across its backside. This high cross section area doubles the rigidity without increasing mass. The exotic fibers cost more and the cones take longer to form, but the result is audibly distinguishable; and to hear the difference of the 9500 is to hear the difference of handmade, USA build quality.

2500W RMS

Made In Oklahoma City, OK, USA.

PREMIUM FEATURES

PREMIUM FEATURES

- NEW Aluminum 2 Stage Motor Heatsink

- 230mm Magnet Diameter

- Multi-Vent Free Flow Cooling Motor

- Shorting Ring Motor

- 3.35” High-Temp Voice Coil

- Excursion Optimized ESP Frame

- V-ROM Vario-Density Surround

- Non-Pressed Composite Reinforced Pulp Cone

- 11” Dual/Triple Layer Iron Cloth Spider

- 9.4″ 5 layer composite spider (9510)

- Laminated Tinsel Leads

- Hand Laid Composite Dust Cap

- Embossed DDesign Magnet Boot

- Made In USA

- Optional Upgrade: SuperCharge

- NEW Aluminum 2 Stage Motor Heatsink

- 230mm Magnet Diameter

- Multi-Vent Free Flow Cooling Motor

- Shorting Ring Motor

- 3.35” High-Temp Voice Coil

- Excursion Optimized ESP Frame

- V-ROM Vario-Density Surround

- Non-Pressed Composite Reinforced Pulp Cone

- 11” Dual/Triple Layer Iron Cloth Spider

- 9.4″ 5 layer composite spider (9510)

- Laminated Tinsel Leads

- Hand Laid Composite Dust Cap

- Embossed DDesign Magnet Boot

- Made In USA

- Optional Upgrade: SuperCharge